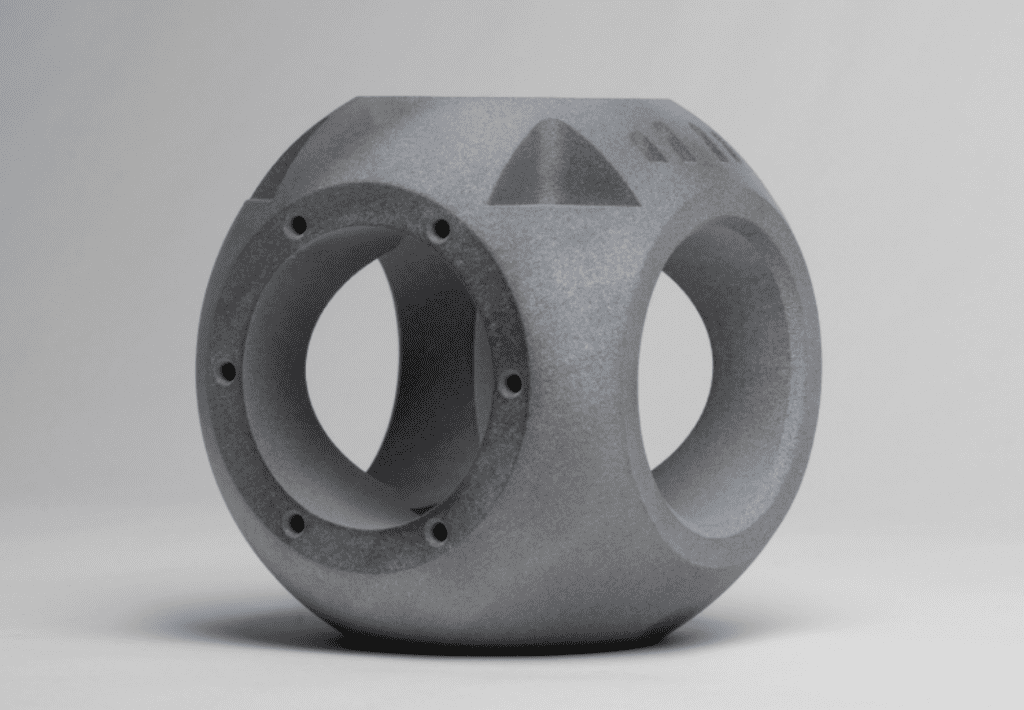

3D Printing for Precision Prototypes

3D printing has become synonymous with rapid prototyping due to its unmatched speed and precision. Whether it’s intricate details or complex geometries, 3D printing allows for the creation of accurate prototypes with minimal time investment. From Fused Deposition Modeling (FDM) to Stereolithography (SLA), the versatility of 3D printing technologies caters to a wide range of prototyping needs.

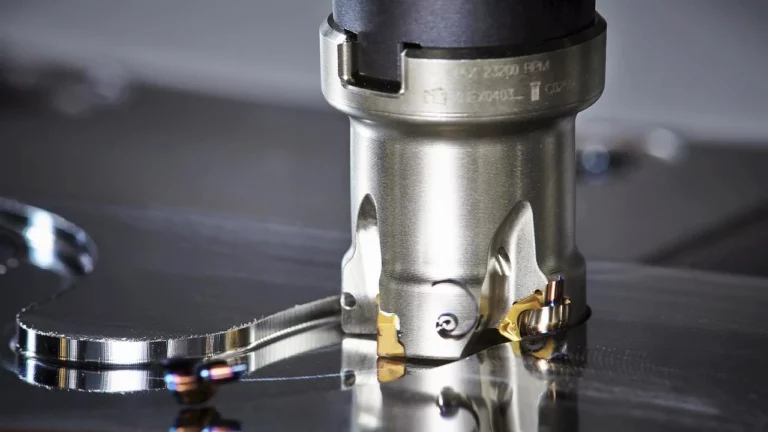

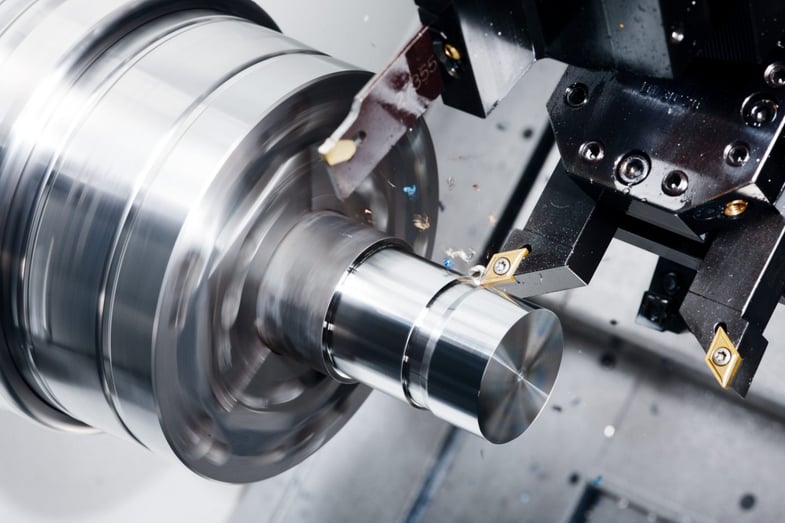

CNC Machining for Functional Prototypes

When functional testing is a priority, CNC machining emerges as a go-to solution. This subtractive manufacturing process ensures the creation of prototypes with materials closely resembling the final product. CNC machining is ideal for producing prototypes that need to withstand real-world conditions, making it a valuable solution for engineers looking to validate functionality early in the design phase.

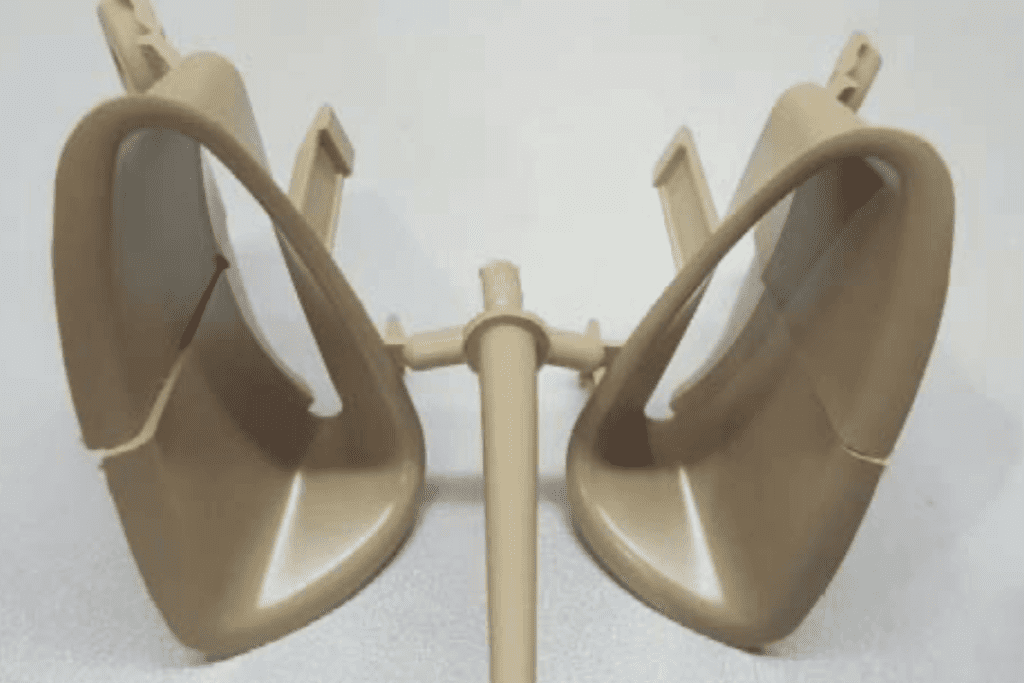

Injection Molding for Production-Grade Prototypes

For those seeking prototypes that mimic the characteristics of mass-produced parts, injection molding is the answer. This process allows for the creation of production-grade prototypes using the same materials and manufacturing techniques planned for full-scale production. Injection molding prototypes offer a cost-effective way to test the scalability and manufacturability of a design.

Sheet Metal Prototyping for Structural Rigidity

When durability and structural integrity are paramount, sheet metal prototyping comes into play. This method is well-suited for products with metal components, providing insights into the performance and durability of the final design. Sheet metal prototypes are often used in industries such as automotive, aerospace, and electronics.

Rapid Tooling for Accelerated Production

Rapid tooling expedites the transition from prototyping to production. By creating molds or tooling quickly and cost-effectively, this solution allows for the efficient scaling up of production processes. Whether it’s injection molding, die casting, or other manufacturing methods, rapid tooling ensures a seamless transition from prototype to final product.

Conclusion

In the competitive landscape of product development, leveraging rapid prototyping solutions is essential for staying ahead of the curve. From 3D printing for swift visualizations to CNC machining for functional validation, and injection molding for production-grade testing, these solutions empower innovators to bring their ideas to market faster and with greater confidence. Embrace the power of rapid prototyping and revolutionize your product development journey for exceptional results.