Automotive seating

With our commitment to quality, you can rest assured that every part we produce is rigorously tested to ensure it meets the highest standards of quality and reliability.

We offer Design For Manufacture analysis (DFM) and PPAP at no additional charge.

- Instant quotes and DFM

- Tight tolerances and finishing capabilities

- CNC parts in as little as 2 days

Why Automotive Companies Choose RP Group

Industry Leading Quality

Quality services include material certifications, certificates of conformity, advanced inspection reports and more

DFM and PPAP Reports

We provide DFM and PPAP reports at no extra charge

Manufacturing Speed

At RP Group, we can provide quotes in minutes and parts in days, automotive engineers can reduce cycle times by as much as 50%

10 x Tighter Tolerances

Compared to other leadings services, RP Group can produce machined parts with tolerances as tight as +/- 0.0002 in, exhibiting 10 times greater precision.

Trusted by Leading Automotive Companies for Seating

- Seat back covers

- Recliner covers

- Head rests and cushion pans

- Map pockets

- Sheet Metal

- Head rest poles

- Wire bending

- Suspension mats

- Soft mold for pre-production build

- in-mold velcro

- Custom bolts

- Cage nuts

- Weight reduction

- Non-woven fabric

- Encapsulation

Prototyping & Production

At RP Group, we take pride in our ability to prototype, and manufacture high-quality car seats that meet the needs of our customers. We ensure that each car seat we produce is optimized for comfort, safety, and durability.

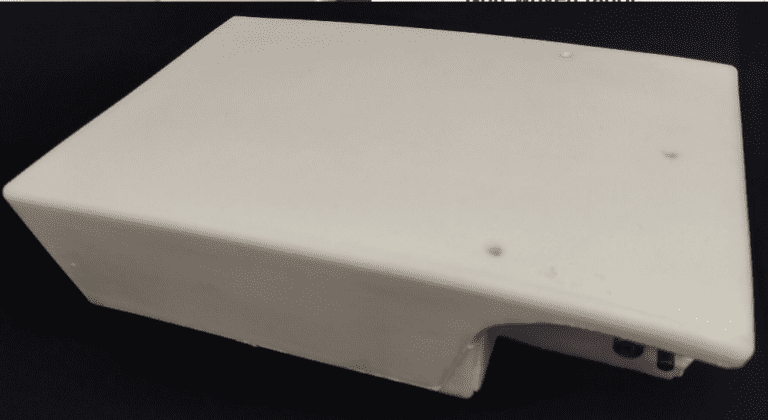

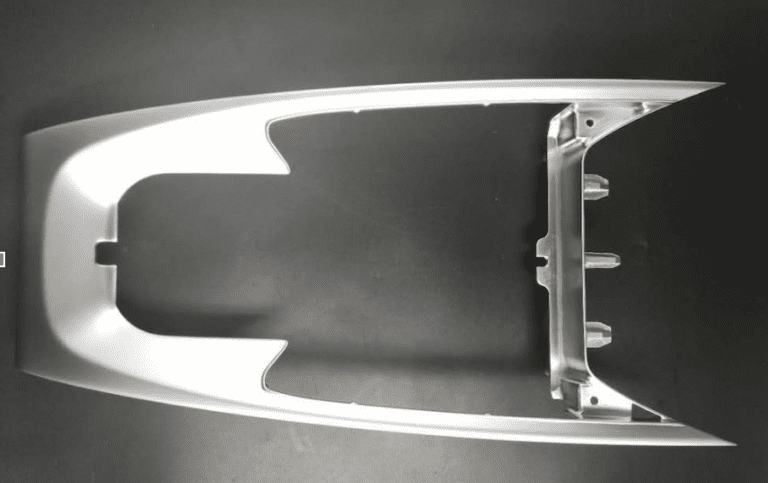

Plastics in Seating

Our car seat plastics are engineered to meet the highest standards of strength and durability. We use processes such as CNC machining and injection-molding using a variety of different plastic materials, including polypropylene, ABS, and nylon, to ensure that each seat is optimised for its intended use.

PUR Foam in Seating

Our experienced team of engineers and designers are highly skilled in the use of PUR foam and are capable of producing car seats that meet the exacting standards of our customers. We understand that each car seat has unique requirements, so we carefully select the appropriate foam material and density to meet the specific needs of each seat design.

Overall, our ability to expertly use PUR foam in the construction of our car seats is a testament to our commitment to producing high-quality products that meet the needs of our customers while also being environmentally responsible

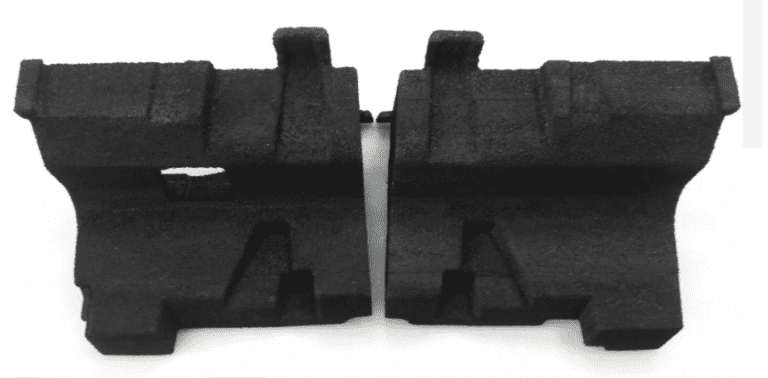

EPP Foam in Seating

We are committed to using the latest technology and materials to produce car seats that are both comfortable and safe. One of the materials we use is expanded polypropylene (EPP) foam.

We use the latest technology and equipment to ensure that our EPP foam is accurately cut and shaped to fit the precise dimensions of each car seat. We also work closely with our suppliers to ensure that the foam we use is of the highest quality and meets all industry standards for safety and performance.

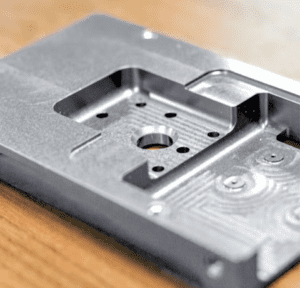

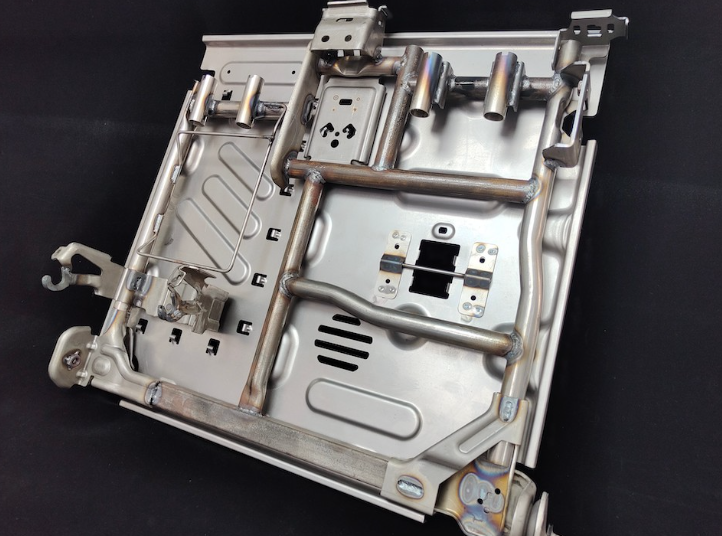

Sheet Metal in Seating

Our capabilities in sheet metal and wire bending allow us to create car seat frames that are strong and lightweight. We use precision-cutting and bending equipment to create precise shapes and angles, ensuring a perfect fit for each car seat.

Our materials range from traditional metals such as steel and aluminum to more advanced composites, giving us the flexibility to create custom designs and meet unique specifications.

Finishes in Seating

We offer a range of finishes for our car seats, including wrapping, painting, chrome plating, textures (MoldTech), wire dipping, and e-coating. These finishes are applied to the car seat frames and other components to provide both an attractive appearance and added durability.

At RP Group, we take great pride in our ability to offer a wide range of finishes for our car seats. Whether you're looking for a simple, cost-effective finish or a more customized, high-end finish, we have the expertise and experience to deliver the perfect solution for your needs.

Automotive Seating Manufacturing Capabilities

Custom Online CNC Machining Services

Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service.

Custom Plastic Injection Molding Service

Get custom plastic molded prototypes and production parts in as few as five business days

Custom Online 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials.