Selective Laser Sintering (SLS)

With the help of selective laser sintering (SLS) 3D printing, it is simple to find high-quality parts for prototyping and manufacturing. Choose from a variety of surface treatments and industrial-grade materials.

The typical lead time for us is only three business days.

Leading-Edge Manufacturing Technology

We use the most advanced manufacturing technology and materials from cutting-edge industry leaders

What is SLS Printing?

The Basics of SLS Printing

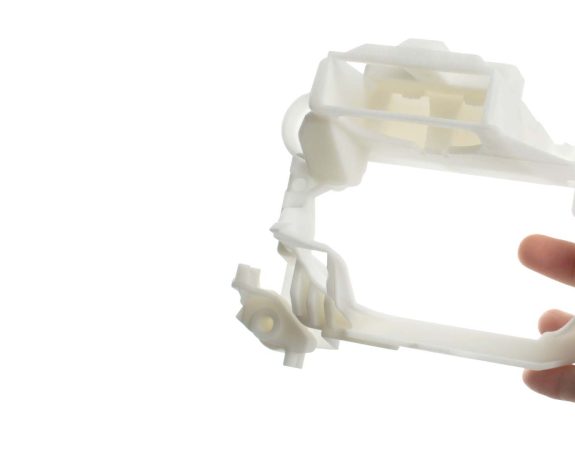

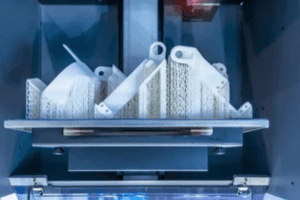

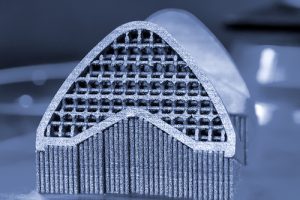

Selective laser sintering (SLS) creates incredibly precise and robust items that may be employed right away in low-volume, end-use manufacturing. SLS is a more recent 3D printing technique that is frequently compared to the well-known metal 3D printing method direct metal laser sintering (DMLS). Both methods use a laser to precisely fuse a powder bed in order to create a part from a 3D CAD file. SLS specialises in using nylon or polyamide powder particles to manufacture components, while DMLS, which is very popular for prototyping and low volume production, employs metal particles.

How SLS Printing Works

High-powered lasers are used in selective laser sintering to bind powdered material together to form solid structures. It is frequently mistaken with Selective Laser Melting (SLM), a related but different process that simply sinters the particles together rather than melting them completely.

High-powered lasers are used in selective laser sintering to bind powdered material together to form solid structures. It is frequently mistaken with Selective Laser Melting (SLM), a related but different process that simply sinters the particles together rather than melting them completely.

Benefits of SLS Printing

It is a popular machining process because it can be used to make parts out of a variety of SLS materials, like plastic, metal, ceramic, or glass powder. Parts can be produced in greater quantities while spending less on labor and materials because SLS does not require a support structure, unlike the majority of other 3D printing technologies. Additionally, the complex internal geometries that 3D manufacturing is capable of producing are less likely to be damaged because the support structure does not need to be removed.

SLS can be used for both low-volume production of functional end-use parts and rapid prototyping. Particularly, nylon is a long-lasting material with high environmental resistance, medium flexibility, and high impact strength. The SLS nylon material is also USP Class VI/121C certified for skin contact and approved by the FDA. SLS is becoming increasingly popular in many industries due to its complexity, design adaptability, material diversity, quick turnaround time, and overall durability.

3D printing processes and materials available at RP Group

Selective Laser Sintering [SLS]

High level of accuracy, relatively cheap raw material, and high temperature resistance make it perfect for a wide range of structural engineering applications.

Materials available: Nylon PA12, Nylon PA12 with glass beads

HP Multi Jet Fusion [MJF]

Multi Jet Fusion can produce functional nylon prototypes and end-use production parts in as little as one day.

Materials available: Nylon PA12, Nylon PA12 with glass beads and polypropylene (PP)

Stereolithography [SLA]

Stereolithography (SLA) creates parts in a layer-by-layer fashion by using photochemical processes whereby light causes chemical monomers to link together to form polymers.

Materials available: ABS natural and ABS clear stimulants.

Binder Jetting

In Binder Jetting, a binder is selectively deposited onto the powder bed, bonding these areas together to form a solid part one layer at a time.

Materials available: Stainless Steel 17-4PH, Stainless Steel 316L, Steel and Sandstone.

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Materials Available: Aluminum

Wax Casting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts. Materials available: Brass, bronze, copper, gold, platinum, silver

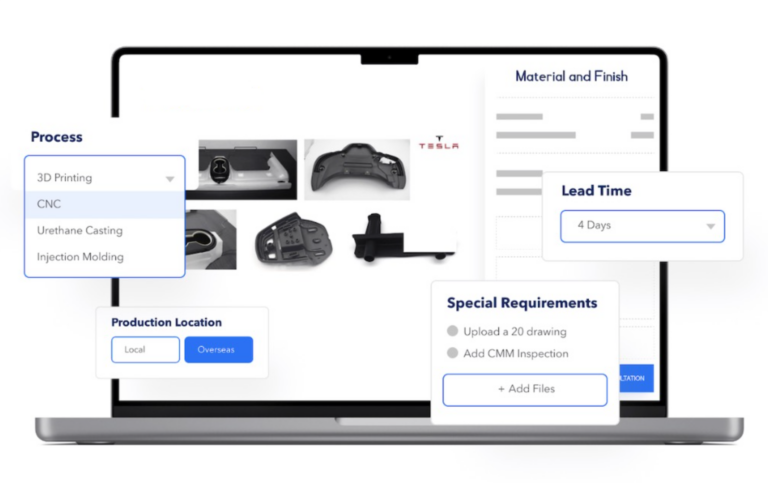

Online instant quoting

Prototyping is all about speed so using our online portal, customers can upload their data and get instant feedback on costs and place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in our online portal

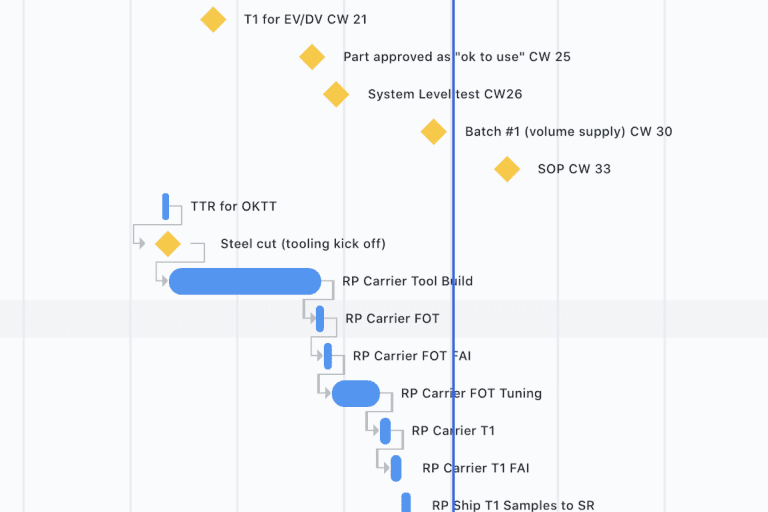

Project management portal and transparent traceability

Keep track of all of your projects on-demand for updates, status and tracking your shipments. The online portal provides a great way to manage complex projects and make seamless communication.

- Track the progress of your project

- Photos and videos of your parts before they ship

- Quality inspection reports online