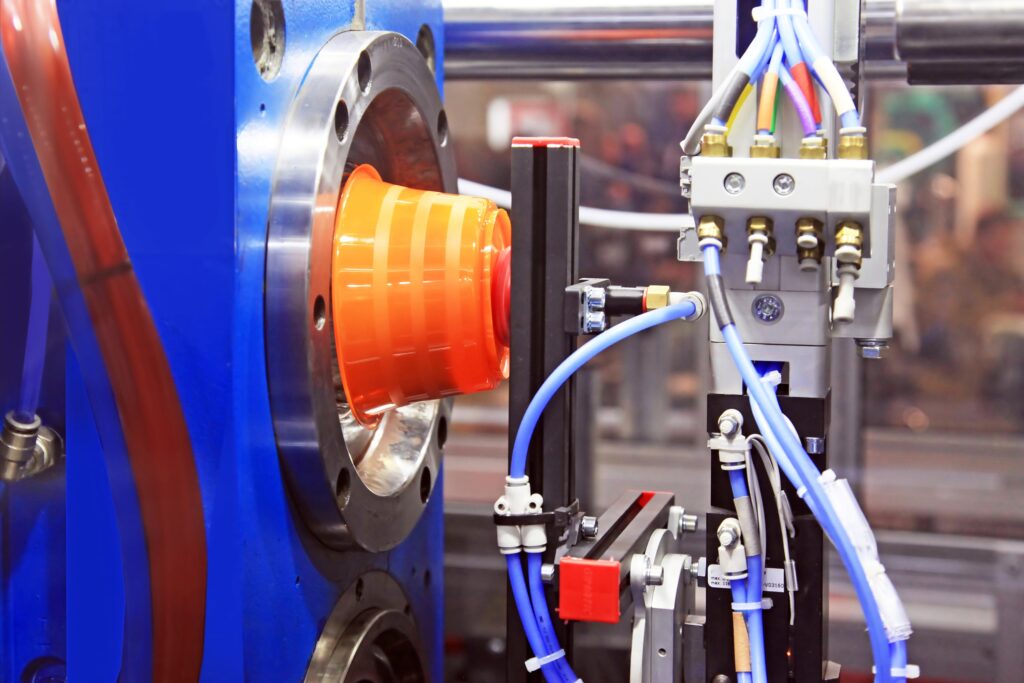

Exploring Injection Molding Tolerances: Strategies for Optimization

Getting injection molding tolerances right is essential for making sure the final parts fit together well. This article will explain how to control these tolerances to guarantee high-quality results through smart design, careful material choices, tool design, and precise process control.